From 0 to 100: Mask production in Switzerland

A Swiss-wide consortium from the research, healthcare and industry sectors is developing innovative mask concepts for efficient protection against viruses as well as technologies for reusing protective materials – not just in the fight against Covid-19, but for future pandemics as well.

Project Diary

“Thanks to the rapid support provided by Innosuisse, we were much more dynamic in this challenging project. Among other things, we set up the entire mask production within a few days.”

Prof. René Rossi

Head of Empa Department Biomimetic Membranes and Textiles

18. March 2020

The Winterthur Cantonal Hospital and the University Hospital Zurich get in touch with EPFL and Empa as the stock of masks is running low. They want to know if there is a way that surgical masks could be used more than once.

The two textile industry associations Swissmem and Swiss Textiles also ask Empa for support. They were commissioned by the federal government’s crisis management team to start mask production in Switzerland.

24. March 2020

Yesterday we spoke with Innosuisse about possible support. We call the project ReMask – short for reusable mask, based on one of the goals of being able to reuse masks. Today we met for the first time as a ReMask team – with 15 individual institutes, epidemiologists and hospitals.

The graphic shows that the types of masks that have been widely used to date – FFP and surgical masks – are only suitable for everyday use to a limited extent, and masks made of simple fabric – known as “community masks” – provide insufficient protection. We will develop a list of criteria that specifies everything a community mask must be able to do.

3. April 2020

The pressing enquiries about the mask shortage are keeping us busy! I have been working at Empa for over 25 years, but have never been so busy at work. Yesterday we conducted the first mask tests at the hospital. There’s also a lot of administration involved. Today, the ReMask team officially joined the expert group of the Swiss National Covid-19 Science Task Force. And we submitted our project to Innosuisse.

28. April 2020

A few days ago, the Science Task Force published the “Community Masks Specifications and Recommendations” policy brief. The ReMask team drew up these quality recommendations for textile masks in just one week. And today we supplemented the application to Innosuisse – focusing on a long-term strategy for mask production in Switzerland.

8. May 2020

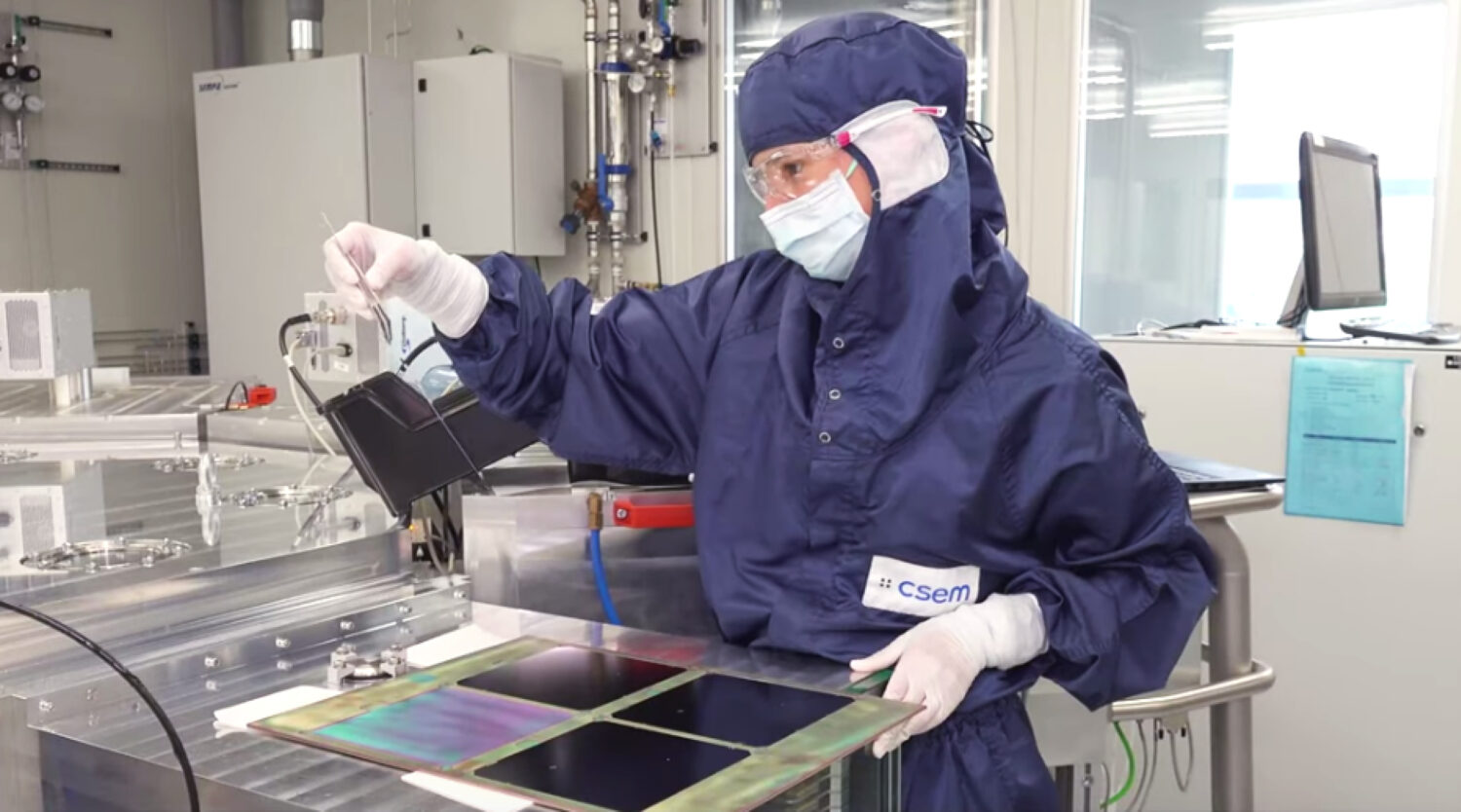

The first mask type from our industrial partners, the textile companies Forster Rohner AG and Schoeller Textil AG in eastern Switzerland, meets the requirements of the Science Task Force. The production of washable community masks in Switzerland can begin!

2. June 2020

After Innosuisse accepted our project submission on 13 May, we are meeting for the first time as the newly formed ReMask team: the associations Swiss Textiles and Swissmem as well as 41 industrial partners are now officially involved.

20. August 2020

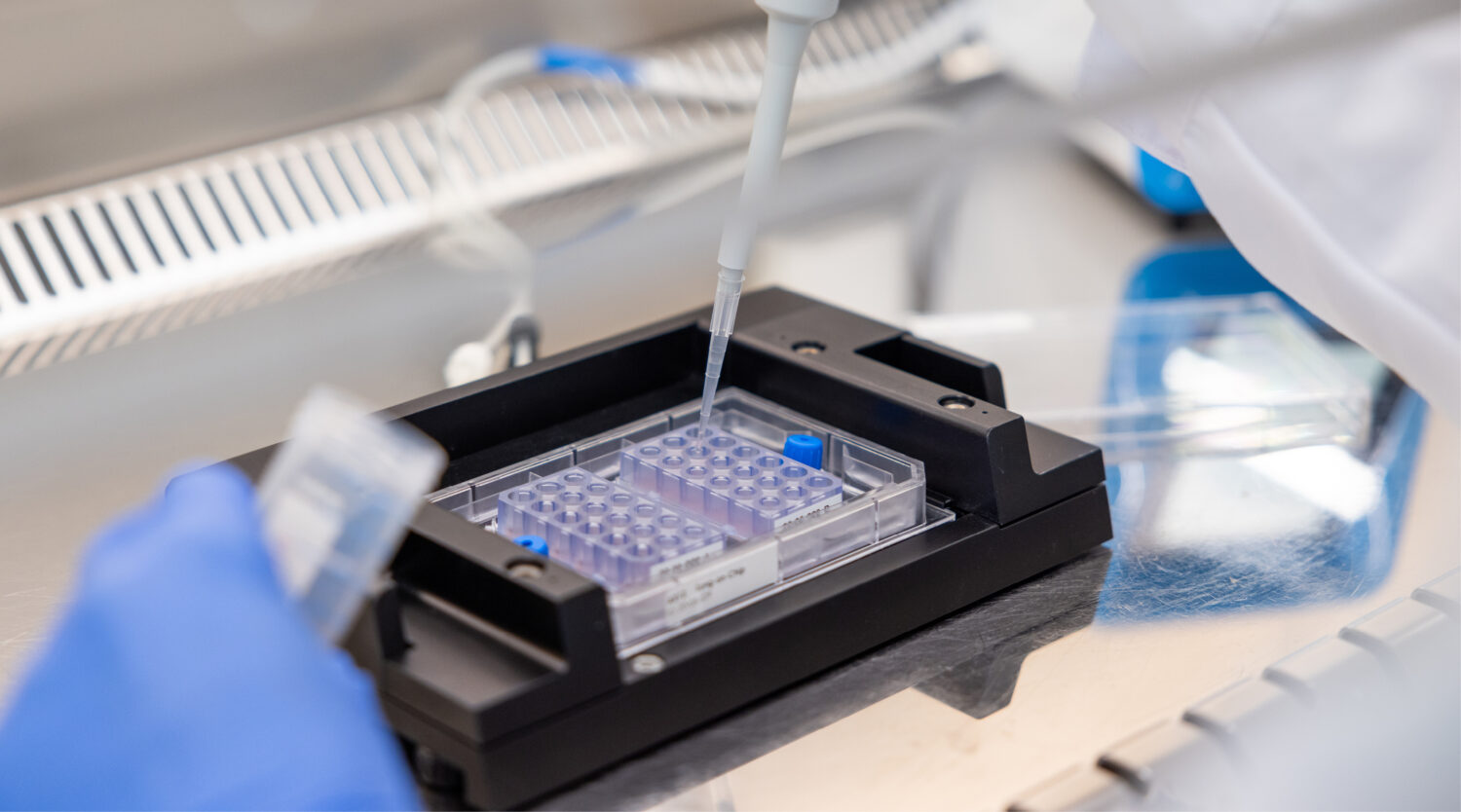

Empa, together with the testing and certification company Testex, has developed a test method in which textile masks can be tested for filter function, splash resistance, wearing comfort, reusability and textile compatibility. The masks made by Schoeller Textil AG and Forster Rohner AG are the first to be awarded the Testex label.

29. September 2020

Another breakthrough! Tests show improved filtration and comfort properties on a laminated nanofibre membrane for the first time. The top layer, which protects against viruses, impairs breathing only minimally.

6. November 2020

After Innosuisse’s go/no-go review, one thing is clear: we’re moving ahead! With a scientific focus on new filter systems with better filtration efficiency and high wearing comfort, fabrics that provide better protection against viruses and bacteria to make masks safer, as well as the reusability of masks – for a sustainable Swiss mask strategy.

8. December 2020

The first reusable textile mask is recognised as a Type I surgical mask pursuant to the EN 14683:2019 standard. Empa is also publishing an initial study on the sustainability of masks. It shows that cotton fabric masks perform better than surgical masks in terms of energy consumption and carbon footprint. In contrast, the surgical mask performs better than its cotton counterpart in terms of water consumption and overall environmental impact.

22. December 2020

The concept for the SNV Swiss regulation for community masks is ready. This uniform standard enables consumers to compare fabric masks from different manufacturers with regard to various parameters such as filter efficiency.

“Enquiries about mask shortages kept us busy.”

Prof. René Rossi

Head of Empa Department Biomimetic Membranes and Textiles

The one-year project has four research objectives:

- High-filtration efficiency for masks that are also particularly comfortable to wear (air and vapour permeability as well as a comfortable fit)

- Efficient virucidal coatings – not only for masks, but also for medical textiles or antiviral covers, for example for seating in trains and airplanes.

- Longevity: Thanks to innovative membranes and virucidal coatings, it should be possible to wear the masks for longer and wash them more often than before and at lower temperatures – without any loss of protective effect.

- Sustainability: Surgical masks should be reusable and thus produce less waste. Research is also being conducted on FFP masks that are biodegradable.

Interview with Emanuel Forster

“We never thought we’d be making masks one day.”

Emanuel Forster

Co-CEO Forster Rohner AG

How did you end up producing fabric masks instead of haute couture and lace lingerie?

In March, all our customers suddenly vanished. All the shops in Italy, France, the USA and the UK closed and the next day we had nothing to do. The fashion industry depends heavily on personal contact, travel and fashion shows.

Through our factories in China, we came into contact with coronavirus early on and we knew that masks were a rare commodity. We thought about how our embroidery machines could be used for the industrial production of masks. In spring 2020, the federal government approached the Textile Federation and we were invited to Bern along with other companies. When the task force issued the minimum requirements for community masks, we were ready: we had already exchanged ideas with other textile companies such as Schoeller and carried out various tests with Empa. From May, we were producing masks together.

Did your employees find the changeover easy?

We quickly put together a cross-group project team (Forster Rohner, Jakob Schlaepfer and Inter-Spitzen): employees from technical production, designers and people who were familiar with made-to-measure products – a great, motivated team. Of course, a change like this is not everyone’s cup of tea: some thought it was a stupid idea to produce masks. A year ago, none of us would have imagined that one day we would be making masks. On the other hand, we in the fashion industry are used to thinking in the short term and working very quickly and flexibly.

Was the coronavirus a burden or even an opportunity for your company?

Even if the mask production helped us to make ends meet until the end of the year, we’re still a long way off the business we would achieve in a normal year. 2020 was a very stressful and nerve-wracking year for us. Those still working had never been so busy as they were last year. In addition, the coronavirus hit individual employees and their families hard in terms of their health. And some of our customers will no longer exist once the crisis is over.

In the medium term, however, the pandemic also offers an opportunity for something new, since everything has been disrupted. We’ve used the time to reflect on what we could do differently and accelerated some plans that were already in the pipeline, such as building projects or restructuring. And we thought about how we could produce more sustainably in future, for example by using less water in the dyeing process.

When the pandemic is over, we’ll be happy to be able to focus entirely on fashion again. As a member of the ReMask project launched by Empa, we’ll also examine whether it is possible to use textile masks in the medical field in the future. Then we will be able to continue to use the wealth of experience we have built up.

Support by Innosuisse

- Innovation Project